Foodservice operations are under increasing pressure to save energy, ensure hygiene, and provide a comfortable working environment. The combination of a heat recovery unit and a heat pump offers a solution that improves air quality in professional kitchens and reduces operating costs by up to 50%.

A controlled kitchen ventilation system is essential to ensure a safe and comfortable working environment that meets both health and safety standards. According to applicable regulations in the Czech Republic (EN16282), heat recovery is required for medium-sized kitchens with an input above 35 kW — typically equivalent to preparing around 50 meals per day.

However, heat recovery adds an economic dimension: with high system efficiency, up to 90% of the heat generated in the kitchen can be reused within the building — for heating, hot water, or even pool heating.

Technology That Heats, Cools, and Purifies the Air

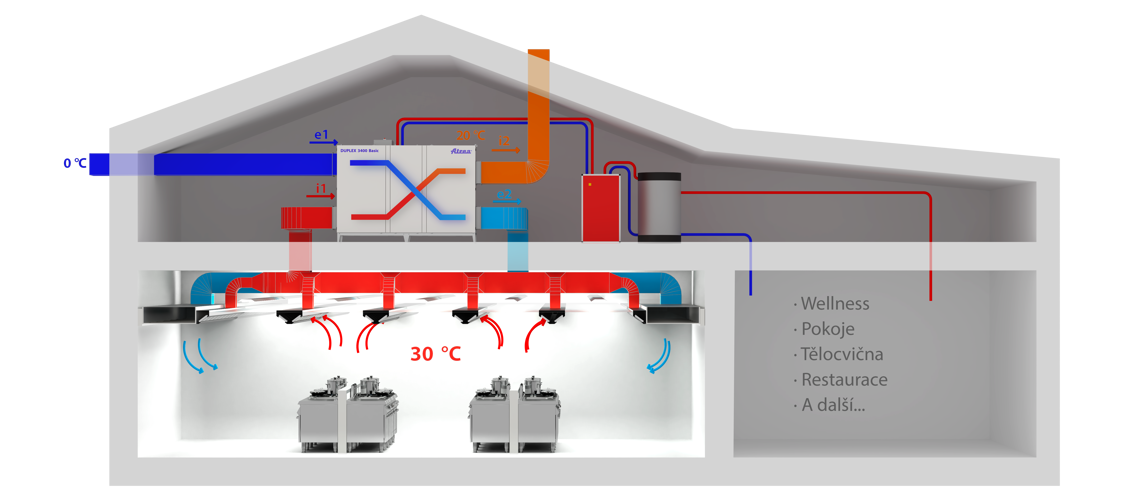

Master Therm, in cooperation with Atrea, offers a comprehensive solution that connects a ventilation and heat recovery unit with a heat pump for efficient energy reuse. The result is a fully integrated system that:

- heats water

- provides heating in winter (e.g., for restaurant areas)

- cools the air in summer – sharp cooling via wall-mounted fan coil units using water at 10 °C ensures higher efficiency and significantly lower operating costs compared to air conditioning

- filters grease, humidity, and airborne particles from kitchen air

Hotel Královka: A Path to Savings

One of the pilot projects is the Královka hotel and restaurant, located in the Jizera Mountains. A professional kitchen ventilation system from Atrea has already been installed.

Ventilation system budget:

- Ventilation ceiling: CZK 1,300,000 (approx. €52,000)

- Air handling unit: CZK 550,000 (approx. €22,000)

- Ductwork and additional expenses: CZK 600,000 (approx. €24,000)

- Total cost: CZK 2,450,000 (approx. €98,000)

The next phase will include the addition of a Master Therm heat pump, which will make the operation more efficient and allow for optimal use of waste heat.

The heat pump, with a capacity of up to 40 kW, will utilize residual heat from the kitchen for space heating and domestic hot water production. This turns the installation into not only an environmentally friendly solution, but also an economically beneficial one. With an initial investment of CZK 500,000 to 700,000 (approx. €20,000 to €28,000), and expected annual savings of approximately CZK 100,000 (approx. €4,000), the return on investment is estimated at 5 to 7 years.

Installation Technical Specifications:

- Airflow: 10,000 m³/h

- Cooling of incoming air via heat pump: 7–8 °C

- Heat pump output: up to 40 kW

- COP: approx. 4 (inlet 7/2 °C, outlet 45/50 °C)

- Average heat output: 28 kW for 7 kW electrical input

Operating Economics:

- Electricity cost: CZK 5/kWh (approx. €0.20)

- Heat value: CZK 2/kWh (approx. €0.08)

- Net savings: CZK 21/hour (approx. €0.84/hour)

- System run time: 14 hours/day, 340 days/year

- Annual savings: approx. CZK 100,000 (approx. €4,000)

Investment Summary:

- Additional cost for heat pump integration: CZK 500,000–700,000 (approx. €20,000–28,000)

- Return on investment: 5 to 7 years

- Long-term savings (15-year operation): CZK 1,500,000 (approx. €60,000)

Discover more about the high-efficiency heat pumps powering this project here.